© 2020 Foshan Quanjiu Industry Automation Co., Ltd. All rights reserved.Site Map Powered by iwonder.cn

Customized Wire Processing Machinery Manufacturer

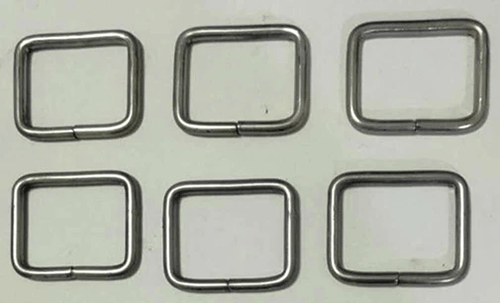

Wire buckles are also called belt buckles. There are many types of wire buckles. Common light-duty conveyor belt wire buckles include pin buckles, spike buckles, butterfly buckles, and zipper buckles.

What equipment is the wire buckle mainly used for? Which industries use hair wire buckles more? With these questions, let our wire buckle making machine manufacturers take you to learn more about the use and precautions of wire buckles.

First of all, the wire buckle is mainly used in the transportation environment where the replacement of the conveyor belt is inconvenient, the equipment is difficult to disassemble and install, the downtime is short, the emergency conveyor belt repair is difficult to install, and the construction period is short.

Therefore, the use of wire buckles greatly enriches the usage scenarios of conveyor belts and improves the production efficiency of conveyor equipment. As long as there is a place for conveying, where there is no special requirement for the conveyor belt joint, it can be connected with a steel wire buckle.

So we have the answer to the first question, what equipment is the wire buckle mainly used for?

First of all, we found that the belts using wire buckles rarely have particularly thin and thick belts, and most of the belts using wire buckles have a thickness of about 2-6mm.

Secondly, the wire buckle can be processed on-site in many cases because it is easy to replace and modify.

That is to say, the use industry of wire buckles has two characteristics:

First: Conveyor belts are often replaced, even in environments where the length needs to be adjusted.

Second: It is difficult to modify the conveyor, and equipment maintenance needs to be done in a short time.

Based on the above characteristics, we have an industry "logistics sorting" that uses a large amount of conveyor belt wire buckles. In a large sorting center, the conveyor belt runs all day, so once the conveyor belt is damaged, the conveyor belt needs to be repaired or replaced as soon as possible. Wire buckle joints have become the first choice for many logistics equipment.

In addition to the logistics industry, conveyor belt buckles are also used in many industries.

There are many applications of wire ropes in slings. The most common method is to make wire ropes into wire buckles by certain means. The production methods generally adopt three methods: braiding, pressing and using wire clips.

So is the safety load of the wire buckle the same as the safety load of the wire rope?

Definitely not. According to the national standard, the safety load of the weaving wire buckle is only 75% of the wire rope. The safety load of the pressed wire buckle is 90% of the wire rope load, so it should be implemented in accordance with the standard of the wire buckle in the application.

There are also some small-caliber steel wire buckle pipe fittings that are mostly used in plumbing, mechanical equipment, chemicals, food factory equipment, and pharmaceuticals.

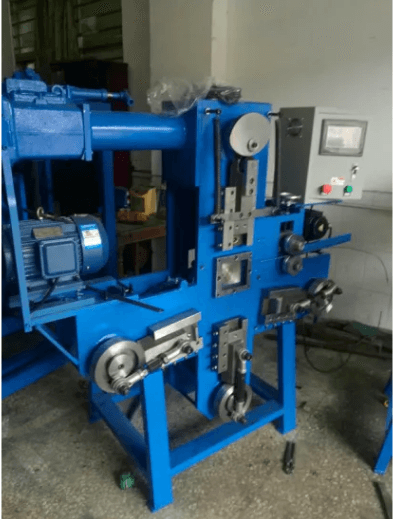

The production of steel buckles is inseparable from the manufacturing machine. If you need to produce a large number of steel buckles, you can log in to our official website to choose the appropriate wire buckle manufacturing machine. Our XLC wire buckle making machine manufacturer will do our best to serve you.