© 2020 Foshan Quanjiu Industry Automation Co., Ltd. All rights reserved.Site Map Powered by iwonder.cn

Customized Wire Processing Machinery Manufacturer

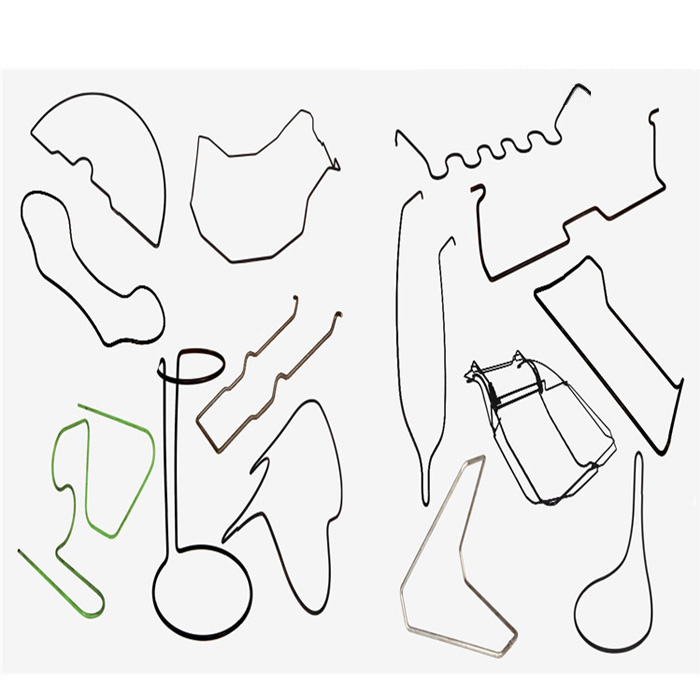

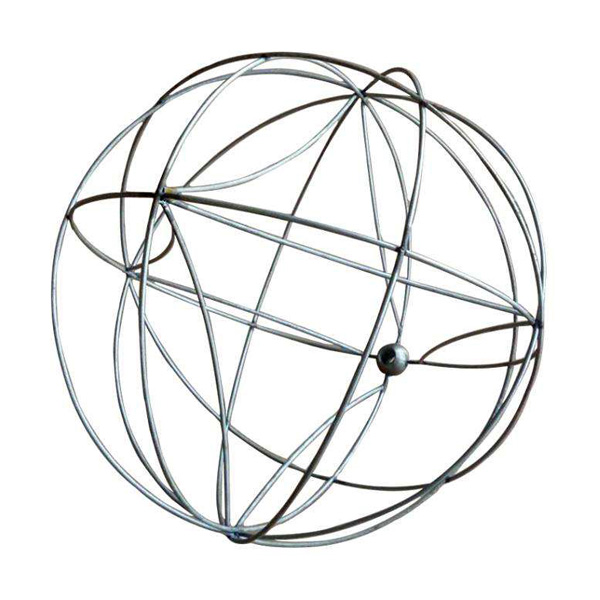

This automatic wire Bending machine is mainly used for bending and forming various metal wire into a different shape in three-dimensional.

Machine parameters:

Model: 3D CNC wire bending machine 3-8mm

Processing wire diameter: ∮3.0mm-∮8.0mm

Number of wire feeding wheel groups: 3 groups

Turning angle: 0°-unlimited

Lifting height of platform: +50mm to -170mm

Lifting height of twisting head: +20mm to -100mm

External torsion lifting height: +20mm to -55mm

Left and right movement range: 80mm to the left, 40mm to the right

The overall forward and backward movement range of the wire feed: forward 300mm, backward 100mm

CNC axes: 8 axes

1.Motor power (kw): | |

1. External torsion motor power | 2.0KW(Japan Sanyo) |

2. Motor power (kw): platform lifting | 1.0KW(Japan Sanyo) |

3. Motor power (kw): Move left and right | 2.0KW(Japan Sanyo) |

4. Motor power (kw): internal torsion | 2.0KW(Japan Sanyo) |

5. Motor power (kw): Overall lifting | 2.0KW(Japan Sanyo) |

6. Motor power (kw): wire feeding | 4.5KW(Japan Sanyo) |

7. Motor power (kw): Wire Rotate | 2.7KW(Japan Sanyo) |

8. Motor power (kw):cutter | 2.0KW(Japan Sanyo) |

Total power (KW) | 18.2KW |

Maximum wire feeding speed: (m/min) | 40M |

Wire feeding accuracy: | 0.1± |

Number of programs that can be supported | 10000 |

Interface language | English |

Connection voltage | 380V |

Machine operating voltage | 220V |

Electricity Capacity (KVA) | 30 KVA |

Machine weight: (kg) | 3100KG |

Machine size: (length * width * height) (m) | 3.5M*1.7M*1.4M |

Maximum load-bearing capacity of automatic wire feeder: (kg) | 500 |

Disc diameter of automatic wire feeder: (m) | 1.2M |

Number of straightening wheels | 18Pcs |

NSK THK | TaiWan ShangYin |

Machine features:

1. The overall twisting head can be offset left and right. (Advantages: internal torsion can be processed eccentrically, and torsion springs can be processed. R angles that can be used are more and more flexible) need to pass through the linear mechanism twice. Make the wire more stable. And when processing long parts, there is more space to move the wire feed box back. Short product time moves forward, making product faster and more stable)

2. The cutting knife can move back and forth (Advantages: the cutting knife can move back and forth, which is faster and more stable when processing short products, and when processing long products, there is more room for retreat, so that the product does not touch the cutting knife)

3. The line can be rotated 360° infinitely. (Advantages: The external motor will not break the motor and inductor wires, it is convenient to process and transfer wires> 360〫 complex products, and the adjustment is quick and convenient)

4. Use new computers. (Advantages: easier to operate, more convenient and faster)

Applicable fields of equipment processing:

1. The field of automobile industry;

Such as: car seat inlays, exhaust equipment, transmission rods, etc.

2. The field of metal thread ends;

Such as: bending thread, transfer joint, suspension elbow, valve buckle, building material molding, etc.

3. Display racks and shelves;

Such as: shelves, shopping trolleys linear forming, etc.

4. Furniture and kitchenware fields;

Such as: oven grid, dish washer basket, etc.

Model No. | 3D004 |

| Axle No. | 8 Axles |

| Wire Diameter | Φ3.0 ~ φ8.0mm; |

Wire Feeding Wheel | 3 Group |

Turning angle | 0°-unlimited |

Lifting height of platform | 50mm to -170mm |

Left and right movement range | 80mm to the left, 40mm to the right |

The overall forward and backward movement range of the wire feed | forward 300mm, backward 100mm |

External torsion motor power | 2.0KW(Japan Sanyo) |

Motor power (kw): platform lifting | 1.0KW(Japan Sanyo) |

Motor power (kw): internal torsion | 2.0KW(Japan Sanyo) |

Motor power (kw): Move left and right | 2.0KW(Japan Sanyo) |

Motor power (kw): Overall lifting | 2.0KW(Japan Sanyo) |

| Motor power (kw): wire feeding | 4.5KW(Japan Sanyo) |

| Motor power (kw): Wire Rotate | 2.7KW(Japan Sanyo) |

| Motor power (kw):cutter | 2.0KW(Japan Sanyo) |

| Maximum wire feeding speed: (m/min) | 40M |

| Wire feeding accuracy | +-0.1 |

| Number of programs that can be supported | 10000 |

| Diameter of automatic wire feeder: (m) | 1.2m |

| Machine Weight | 3100kgs |

Dimension | 3500x1700x1400 mm |

Wheels |

|

|

Polywood Packaging |

Wheels |

Do you have any questions or an issues we can help you with?