© 2020 Foshan Quanjiu Industry Automation Co., Ltd. All rights reserved.Site Map Powered by iwonder.cn

Customized Wire Processing Machinery Manufacturer

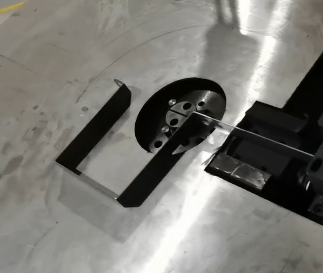

This automatic wire Bending machine is mainly used for bending and forming various metal wire into a different shape in two-dimensional.

2D CNC Fully Automatic Wire Bending Machine is mainly used for bending and forming various metal wires into different shapes in two-dimensional.

The wire feeding and rotary bending system both adopt servo motor, significantly improves the precision of the product, and increases the speed and flexibility of the machine effectively, furthermore greatly improves the production efficiency.

According to the characteristics of wire processing, various types and shapes, we specially design the controlling system with a memory storage function, which can save more than 10000sets of processing program for different products, can optionally select any one of them when needed.

Model No. | 2-6mm | 2-8mm | 4-12mm | 5-10mm |

| Electrical Voltage | 3-phase 380v + ground wire | 3-phase 380v + ground wire | 3-phase 4-wire+ ground wire | 3-phsse 4-wire+ ground wire |

Wire Straightening Wheel No. | 22 Groups (Adopt national standard Cr12) | 22 Groups (Adopt national standard Cr12) | 24 Groups (Adopt high quality steel 45#) | 24 Groups (Adopt high quality steel 45#) |

Bending Die | High quality material SKD11/51 with fine processing hardness up to 62° | High quality material SKD11/51 with fine processing hardness up to 62° | High quality material with fine processing hardness up to 62° | High quality material with fine processing hardness up to 62° |

Wire Feeding Wheel No. | 3 Group (The wire feeding wheel adopts national standard Cr12 and fine polishing processing heat treatment with hardness up to 58°and high wear resistance. ) | 3 Group (The wire feeding wheel adopts national standard Cr12 and fine polishing processing heat treatment with hardness up to 58°and high wear resistance. ) | 4 Group (The wire feeding wheel adopts national standard Cr12 and fine polishing processing heat treatment with hardness up to 58°and high wear resistance. ) | 4 Group (The wire feeding wheel adopts national standard Cr12 and fine polishing processing heat treatment with hardness up to 58°and high wear resistance. ) |

Servo Motor Power | 3.8KW Wire Feeding Belt Deceleration + 1.5 KW Wire Bending Belt Deceleration + 3KW Ordinary Oil Pump Motor | 3.8KW Wire Feeding Belt Deceleration + 1.5 KW Wire Bending Belt Deceleration + 3KW Ordinary Oil Pump Motor | 8.35kw 3.8kw Wire Feeding + 3.8 kw Wire Bending + 4kw Ordinary Motor Cutter | 12.35kw 3.8kw Wire Feeding + 3.8 kw Wire Bending +0.7kw lifting+ 4kw Ordinary Motor Cutter |

Cutter Oil Cylinder Cutting Force | Ø6 Iron Wire | Ø8 Iron Wire | Ø12 Iron Wire | Ø10 Iron Wire |

Oil Pressure Range | 0.3-0.8mpa | 0.3-0.8mpa | 0.3-1mpa | 0.3-1mpa |

Hydraulic Oil | 46#68# | 46#68# | 46#68# | 46#68# |

Suitable Wire | Round Wire, Flat Wire, Square Wire (Suitable for any wire material) | Round Wire, Flat Wire, Square Wire (Suitable for any wire material) | ||

Suitable Wire Range | 2-6mm Iron Wire Standard | 2-8mm Iron Wire Standard | 4-12mm Iron Wire Standard | 5-10mm Iron Wire Standard |

Machine Dimension | 2800*850*1500mm | 2800*850*1500mm | 3700*850*1580mm | 3700*850*1580mm |

Machine Weight | 1100 KGS | 1100 KGS | 1580 KGS | 1580 KGS |

Perimeter Scope | No Limit | No Limit | No Limit | No Limit |

Storage | 10000 Groups of Data, 300 Actions/ Group | 10000 Groups of Data, 300 Actions/ Group | 10000 Groups of Data, 300 Actions/ Group | 10000 Groups of Data, 300 Actions/ Group |

Wire Feeding Speed | 100m-150m/min | 50m-100m/min | 40-47m/min | 40-47m/min |

Max Wire Bending Speed | 80-160 R/min Angle ±180° | 60-115 R/min Angle ±180° | 40 R/min Angle ±180° | 50 R/min Angle ±180° |

Action Direction | Inner Mold: Move Down/ Up; Outer Mold: Move Down/ Up Turn 360° by clockwise direction or anti-clockwise direction. | Inner Mold: Move Down/ Up; Outer Mold: Move Down/ Up Turn 360° by clockwise direction or anti-clockwise direction. | Inner Mold: Move Down/ Up; Outer Mold: Move Down/ Up Turn 360° by clockwise direction or anti-clockwise direction. | Inner Mold: Move Down/ Up; Outer Mold: Move Down/ Up Turn 360° by clockwise direction or anti-clockwise direction. |

Efficiency | 20-25pcs/ min (Based on the square wire of 200*200mm) | 16-20pcs/ min (Based on the square sample of 200*200mm) | 8-10pcs/ min (Based on the square sample of 200*200mm) | 8-10pcs/ min (Based on the square sample of 200*200mm) |

Bending Precision | ±0.5mm | ±0.5mm | ±0.5mm | ±0.5mm |

| Wire Feeding Precision | ±0.5mm | ±0.5mm | ±0.2mm | ±0.2mm |

Pressure Regulating Valve | Yes | Yes | Yes | Yes |

| Decompression Regulatign Valve | - | - | Yes | Yes |

| Magnetic Valve | 4 pcs | 4 pcs | 4 pcs | 4 pcs |

| Motor OIl Pump | 1 pc | 1 pc | - | - |

| Motor | 1 pc | 1 pc | - | - |

| Oil Plate | 1 pc | 1 pc | 1 pc | 1pc |

| Pressure Gage | - | - | - | 1pc |

| Cooling Pump | - | - | - | 1pc |

Language System | English/ Chinese (With search, uploading and downloading function) | English/ Chinese (With search, uploading and downloading function) | English/ Chinese (With search, uploading and downloading function) | English/ Chinese (With search, uploading and downloading function) |

Max Torque | - | - | 600 N.M | 300 N.M |

| Max Bending | 400 N.M | 560 N.M | - | 600 N.M |

Control Panel | Button | Button | Touching Screen- MCGS | Action Control System |

Control Module | 32 bits High Performance Processor | 32 bits High Performance Processor | 32 bits High Performance Processor | 32 bits High Performance Processor |

Wheels |

|

|

Polywood Packaging |

Protective Cover |

Do you have any questions or an issues we can help you with?