© 2020 Foshan Quanjiu Industry Automation Co., Ltd. All rights reserved.Site Map Powered by iwonder.cn

Customized Wire Processing Machinery Manufacturer

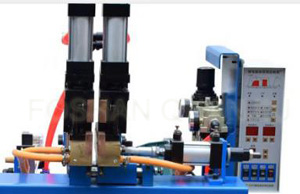

Pneumaitc Butt Welding Machine:100KVA

【Welding Machine Features and Application】

Welder UN- serious is used to weld ferrous and nonferrous metals and their alloy wires, rods, tubes, plates and other materials by heating resistance. The clamping of weldments and the pressure of upsetting force are all pneumatic. The pressure cylinder is a double piston rod buffer cylinder and is equipped with welding force buffer fine adjustment device which improves the welding reliability of fine wire conductor. The key parts of the welder are imported components, such as solenoid valve and thyristor module, which are imported with high speed and precision. This is the newest pneumatic butt welding machine.

【Standard Model and Specification】

Model No. | Input Voltage | Rated Power | Max Pressure | Max Upsetting Force | Rated Welding Section |

V/Hz | KV.A | KG.F | KG.F | mm2 | |

100KVA | 380-50 | 100 | 3200 | 2100 | 430 |

【Structure Brief Description 】

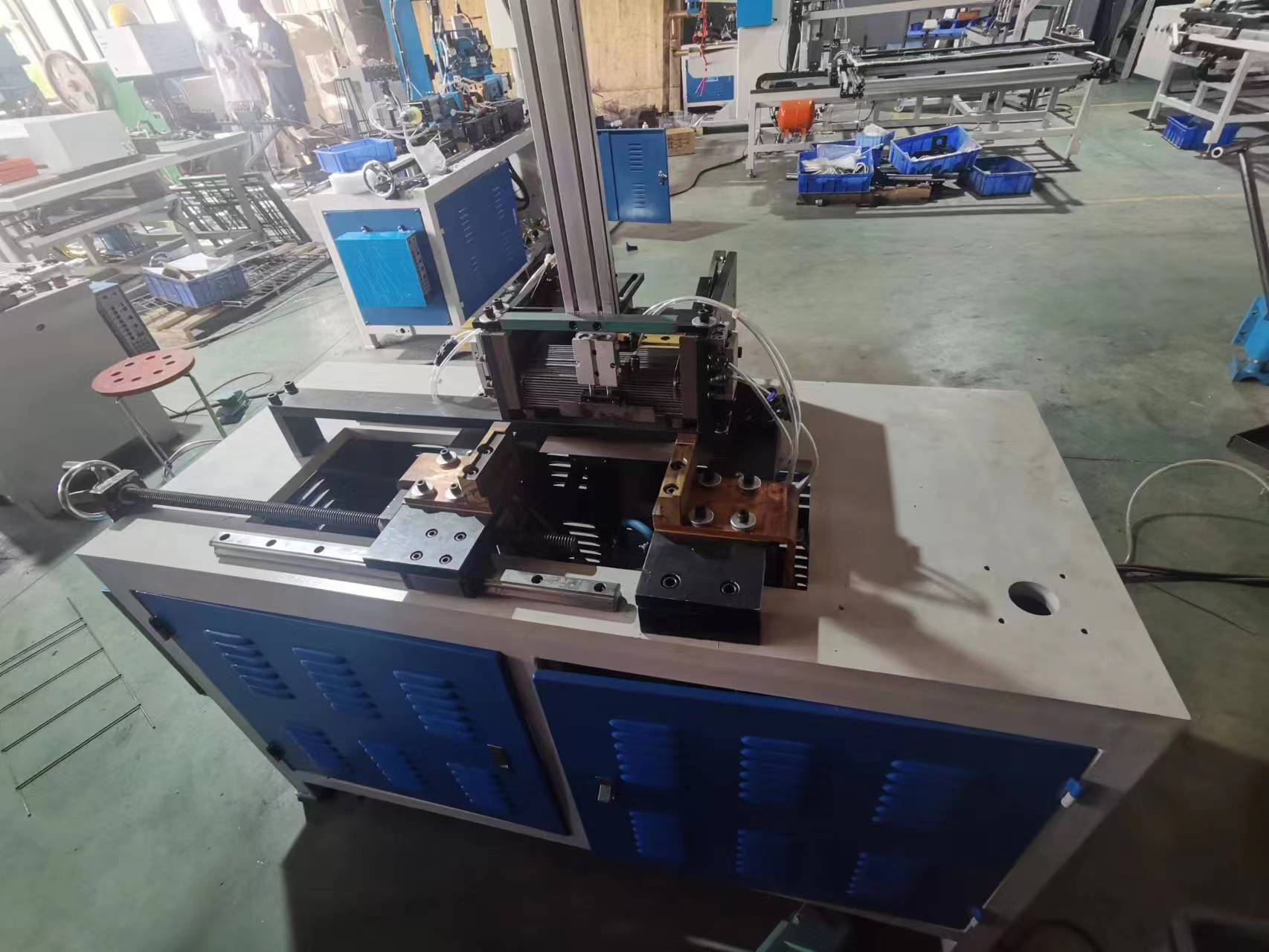

Mechanical Structure:

The machine adopts platform type and the machine body is steel structure. The fixed clamp and the adjustable clamp are equipped on the surface of table. The welding transformer is installed in the machine body. The machine adopts the pneumatic clamping and welding force with convenient installation and debugging. It is the newest type of butt welding machine.

1)Main Power Circuit and Control Box

The main power circuit uses two anti-parallel thyristor as the power switch, and the on-off time is controlled by the control box.

The controller has seven procedures of pre-pressure, slow lift, heat 1/11, pressure holding, pause and cooling, and has the function of "welding/adjustment", "single point/continuous", "pressure/work" . The input voltage of the controller is two-phase AC380V.

In addition, slow lifting time is used to control the current to increase gradually and improve the quality of welding spot.

3)The "pause time" of UN series welder is used to control the action time difference between upper and lower pressure cylinder and top forging cylinder.

【Welding Machine Installation】

The welding machine is powered by two-phase 380V, 50HZ. The power cord and fuse or automatic switch can be selected according to the capacity of the welding machine. See table below for installation requirements. The welder should be grounded reliably with earthing bolts at the back of the fuselage.

The welder shall be installed on the flat cement floor, and the anchor bolt shall be installed to fix welder;

3、Water inlet and outlet are installed on the side of the welder. The water pressure should not exceed 0.01Mpa. Please connect the water channel.

4、There is an air inlet on the air source processor and the air source pressure is 0.1-0.7mpa. The compressed air is connected with the ordinary air pipe.

Model No. | Cooling Water | Compressed Air | ||||

Voltage | Water Pressure | Flow | Pressure | Air Supply Pipe Diameter | ||

V | Kgf/cm | L/min | Kgf/cm | mm2 | ||

100KVA | 380 | 2-3 | 8 | 1-7 | Φ20 | |

| Rated Capacity | 100 KVA |

| Power Supply | 3 Phase, 380V, 50HZ |

| Rated Frequency | 50/60HZ |

| Max Short Circuit Current | 28KA |

| Machine Dimension | 1000*900*1500mm |

| Machine Weight | 550 kgs |

| Max Fastening Force | 3000N |

| Cooling Water | 150 |

Do you have any questions or an issues we can help you with?