© 2020 Foshan Quanjiu Industry Automation Co., Ltd. All rights reserved.Site Map Powered by iwonder.cn

Customized Wire Processing Machinery Manufacturer

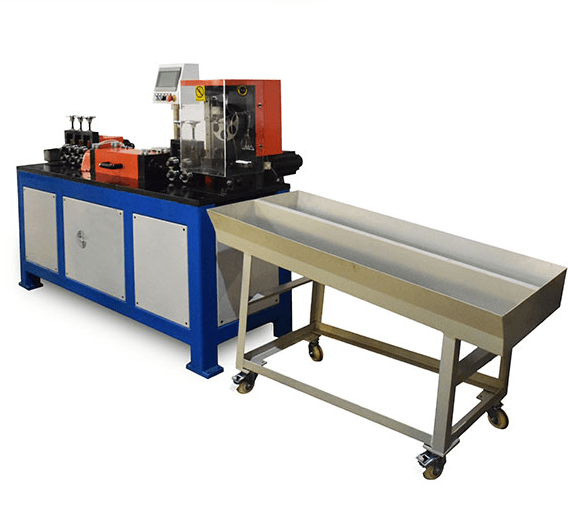

The cutting machine is a lathe machine that we are familiar with, it is used to cut objects. However, what this article wants to introduce to you is the wire cutting machine. Although they are only one word difference, the two are really different. So what is a wire cutting machine? What is its working process? And what are its main applications? Let’s follow XLC ’s editor to take a look!

Introduction of wire cutting machine application:

The wire cutting machine is mainly composed of three parts: a machine tool, a numerical control system and a high-frequency power supply. The numerical control system is composed of a single-chip microcomputer, a keyboard, and a frequency conversion detection system. It has the main functions of gap compensation, linear interpolation, circular interpolation, and automatic processing of broken wires. It can cut materials, such as high-strength, high toughness, high hardness, high brittleness, magnetic materials, and precision small and complex-shaped parts. Wire cutting technology and wire cutting machine tools are being widely used in all walks of life.

Working principle:

1. Fully understand the performance, structure and correct operation steps of the machine tool before starting up.

2. Check whether the travel switch and reversing switch of the machine tool are safe and reliable, and work with faults is not allowed.

3. Processing should be carried out within the allowable specifications of the machine tool, and do not work with overweight or over-travel.

4. The specified lubricating oil or grease should be injected into the lubricating part regularly according to the regulations. In order to ensure the flexible operation of the mechanism, especially the reverser and bearings, they must be regularly checked and replaced.

5. Before processing, check whether the working fluid in the working fluid tank is sufficient, whether the water pipes and nozzles are unblocked, and there should be no blockage.

6. Check whether the program coordinate direction is consistent with the work piece installation coordinate direction.

7. It is forbidden to touch the work piece and wire frame during processing to avoid electric shock.

8. At the end of the internship, the working area should be cleaned up, and the fixtures and accessories should be wiped clean and put back into the toolbox, and kept intact.

9. Regularly check whether the machine's electrical appliances and performance are reliable and clean up dust to prevent metal objects from falling into it.

10. It is forbidden to plug or unplug the floppy disk when the drive is working.

Wire cutting has many incomparable advantages, such as: wire cutting has small machining allowance, wire cutting has high processing accuracy, wire cutting has short production cycle, wire cutting has low manufacturing cost and other outstanding advantages, wire cutting is already in production Get a wide range of applications. Wire straightening and cutting machine can run normally, must meet the following conditions:

1. A certain gap must be maintained between the molybdenum wire and the processed surface of the work piece. The width of the gap is determined by the working voltage, the processing volume and other processing conditions.

2. Pulse power must be used, that is, the spark discharge must be pulsed and intermittent. In the pulse interval, the gap medium is eliminated ionization, so that the next pulse can break down and discharge between the two poles.

Our wire straightening and cutting machine has many advantages. If you need it, you can visit our website and we will try our best to serve you.