© 2020 Foshan Quanjiu Industry Automation Co., Ltd. All rights reserved.Site Map Powered by iwonder.cn

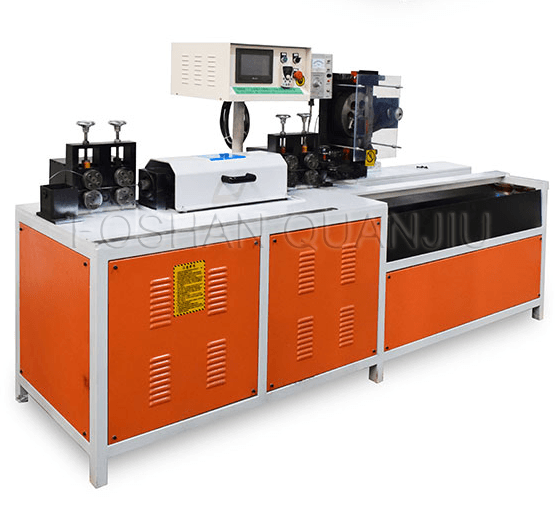

Customized Wire Processing Machinery Manufacturer

With the development of the modern mechanical processing industry, the requirements for cutting quality and precision are constantly improving, and the requirements for improving production efficiency, reducing production costs, and having high-intelligence automatic cutting functions are also increasing. Today we are going to talk about how to maintain and maintain the wire cutting machine.

1. After the operation is completed, use tap water to rinse the slag on the surface of the studio and workbench and wipe dry.

2. Regularly clean the oil stains on the carriage, guide rail and guide rail drive screw rod, and fill in lubricating oil in time.

3. After all the work is over, move the blade about 10 cm forward to reset the rocker arm of the travel switch.

4. If the whole wire cutting machine is not used for a certain period of time after use, the moving parts of the blade and the fixture and some rusty places in the machine should be coated with a layer of lithium.

Daily maintenance and maintenance:

1. The dirt on the machine tool and guide rails must be cleaned every working day to keep the machine bed clean. Turn off the air source and power supply when off work, and at the same time empty the remaining air in the machine tool tube.

2. If you leave the machine for a long time, turn off the power to prevent non-professional operation.

3. Pay attention to observe whether there is lubricating oil on the surface of the machine's horizontal and longitudinal guide rails and racks to keep them well lubricated.

Weekly maintenance and maintenance:

1. The machine should be cleaned up every week, the horizontal and vertical guide rails, the transmission gear rack should be cleaned, and the lubricating oil should be added.

2. Check whether the horizontal and vertical rail wipers are working properly, and replace them in time if they are abnormal.

3. Check whether all the cutting torches are loose, clean up the rubbish of the ignition muzzle, and keep the ignition normal.

4. If there is an automatic height adjustment device, check whether it is sensitive and whether to replace the probe.

5. Check whether the plasma cutting nozzle and electrode are damaged, and whether the cutting nozzle and electrode need to be replaced.

Monthly and quarterly maintenance:

1. Check whether there is rubbish at the main air inlet, and whether each valve and pressure gauge are working properly.

2. Check whether all the air pipe joints are loose, and all the pipes are not damaged. Tighten or replace if necessary.

3. Check whether all transmission parts are loose, check the meshing of gears and racks, and make adjustments if necessary.

4. Loosen the tightening device and push the pulley by hand to see if it can come and go freely. If there is any abnormality, adjust or replace it in time.

5. Check the clamping block, steel belt and guide wheel for looseness and tightness of the steel belt, and adjust if necessary.

6. Check the performance of all buttons and selector switches, replace damaged ones, and finally draw a comprehensive inspection graph to test the accuracy of the machine.

I hope that our XLC introduction on the maintenance and maintenance of wire cutting machines can help you. If you have a need for the product, you can go to our website to have a look.